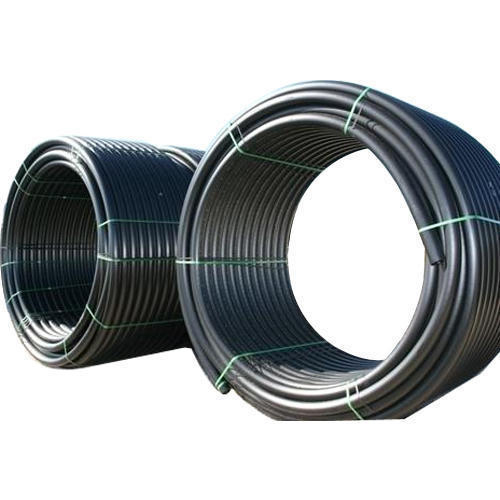

HDPE Coil Pipes

70 INR/Meter

Product Details:

- Application Drinking Water, Utilities Water, Chemical Handling, Gas Handling

- Material HDPE

- Shape Round

- Length 18 Meter (m)

- Diameter 1/2 to 2 Inch (in)

- Color Black

- Click to view more

X

HDPE Coil Pipes Price and Quantity

- 1000 Meter

- 70 INR/Meter

HDPE Coil Pipes Specification

- Round

- HDPE

- Drinking Water, Utilities Water, Chemical Handling, Gas Handling

- 1/2 to 2 Inch (in)

- Black

- 18 Meter (m)

HDPE Coil Pipes Trade Information

- 10000 Meter Per Day

- 2-7 Days

Product Description

We are a profound manufacturer of HDPE Coil Pipes for our highly honoured clients. They are made in a variety of sizes and specifications for numerous industrial applications. Our personnel use premium quality HDPE and other material for making these pipes in compliance with the industrial set standards and norms. These pipes are thoroughly inspected on different parameters, ensuring high strength, precise design, durability and fine finishing. They are offered by us at industry leading prices.

Apart from industrial applications, HDPE Coil pipes can be used in residential, transportation and agriculture applications. This kind of pipe can be installed under the ground. This flexible pipe leak-proof, tough, strong, and can resist temperature, chemical, weathering and abrasion. Available in the form of coil, the HDPE pipe has smooth inner surface so that liquid can flow at right speed. Material that can be transported using this pipe can be many, from edible oils, juices, chemicals, acids to treated waste.

FAQ:

1. What is HDPE coil pipe?

Ans: HDPE coil pipe is a type of plastic pipe made from high-density polyethylene material. It is manufactured in a coiled form, making it easy to transport, handle, and install. HDPE coil pipes are known for their excellent flexibility and resistance to various chemicals, making them suitable for a wide range of applications.

2. What are the applications of HDPE coil pipes?

Ans: HDPE coil pipes find applications in agriculture (irrigation), water supply, gas distribution, cable protection, industrial processes, sewage systems, and more. Their flexibility and corrosion resistance make them versatile for both above-ground and buried installations.

3. What are the advantages of using HDPE coil pipes?

Ans: HDPE coil pipes offer several benefits, including high flexibility, excellent resistance to corrosion and chemicals, lightweight construction, long lifespan, and low maintenance requirements. They are also cost-effective in the long run due to their durability and reduced need for repairs or replacements.

4. How are HDPE coil pipes installed?

Ans: HDPE coil pipes are installed using various methods, including open trench installation, horizontal directional drilling (HDD), and plowing. The coiled design simplifies installation and reduces the number of joints, minimizing the potential for leaks. They are joined using heat fusion techniques, such as butt fusion or electrofusion, to create strong and leak-free connections.

5. Can HDPE coil pipes be used for potable water?

Ans: Yes, HDPE coil pipes are commonly used for potable water systems. HDPE is approved for drinking water applications by regulatory agencies, as it does not leach harmful chemicals into the water and is resistant to biological growth. However, it's important to ensure that the specific HDPE material being used is certified for potable water use.

6. What is the lifespan of HDPE coil pipes?

Ans: HDPE coil pipes are known for their long lifespan, which can exceed 50 years or more when installed and maintained correctly. They are highly resistant to environmental factors, including UV radiation, chemical exposure, and waterborne contaminants, contributing to their extended service life.

7. Are HDPE coil pipes environmentally friendly?

Ans: HDPE coil pipes are considered more environmentally friendly compared to other materials like metal pipes. HDPE is recyclable and has a lower carbon footprint during its production and transportation. Its longevity and resistance to corrosion also reduce the need for frequent replacements, further reducing environmental impact.

8. What sizes are available for HDPE coil pipes?

Ans: HDPE coil pipes are available in a range of sizes, typically ranging from 1/2 inch to 2 inches in diameter. The specific sizes available can vary based on manufacturers and regional standards.

9. What is the difference between HDPE coil pipes and traditional rigid pipes?

Ans: HDPE coil pipes differ from traditional rigid pipes (such as PVC or metal pipes) mainly in their flexibility and installation methods. HDPE coil pipes are coiled for easy transport, reducing the need for numerous joints. Their flexibility allows them to adapt to terrain changes and ground movement, which can be particularly advantageous in areas prone to earthquakes or soil shifts.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free